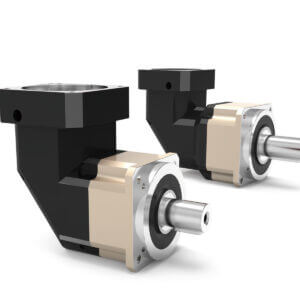

Description

Parameter details

| Output flange dimensions: | 40 mm, 60 mm, 90 mm, 120 mm, 160 mm, square. | |

| Output torque range: | Rated 20 N·m – 450 N·m; Maximum output: three times the rated value. | |

| Available gear ratio | Level 1 | 3/4/5/6/7/8/10 |

| Two phases | 12/15/20/25/30/35/40/50/60/70/80/100 | |

| gap | Level 1 | P2≤7arcmin |

| Two phases | P2≤9arcmin | |

Features

- 1. The gear material is made of high-quality alloy steel and undergoes carbonitriding heat treatment to obtain the best wear resistance and impact toughness.

- 2. ANSYS technology is used to perform finite element analysis on gear strength, and the tooth profile and lead are corrected to reduce the impact and noise of gear meshing and increase the service life of the gear system.

- 3. The output planetary carrier adopts an integrated (double-support) structural design, with the front and rear bearings distributed in the large-span housing to form a stable integrated structure, ensuring high torsional stiffness and accuracy.

- 4. The gear ring and output housing are integrated into a single unit, made of high-quality steel and hot-forged to achieve higher material density. This integrated design ensures that all geometric dimensions are machined simultaneously. It offers higher precision and strength compared to other embedded or clamping structures.

- 5. The input shaft and locking device adopt an integrated design with symmetrically distributed double bolts to achieve dynamic balance. At the same time, the strong locking of the double bolts effectively prevents the motor shaft from slipping, achieving high-precision, zero-backlash power transmission.

Product Application

- 1. Aerospace and military industry.

- 2. Healthcare and electronic information industries.

- 3. Industrial robots, production automation, and CNC machine tool manufacturing industries.

- 4. Automobile, textile, printing, food, metallurgy, environmental engineering, warehousing and logistics industries.